- Our Solutions & Capabilities

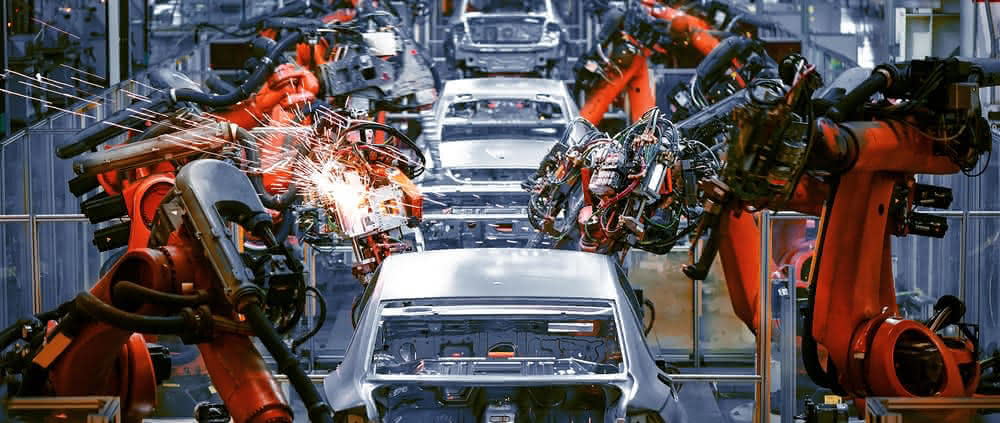

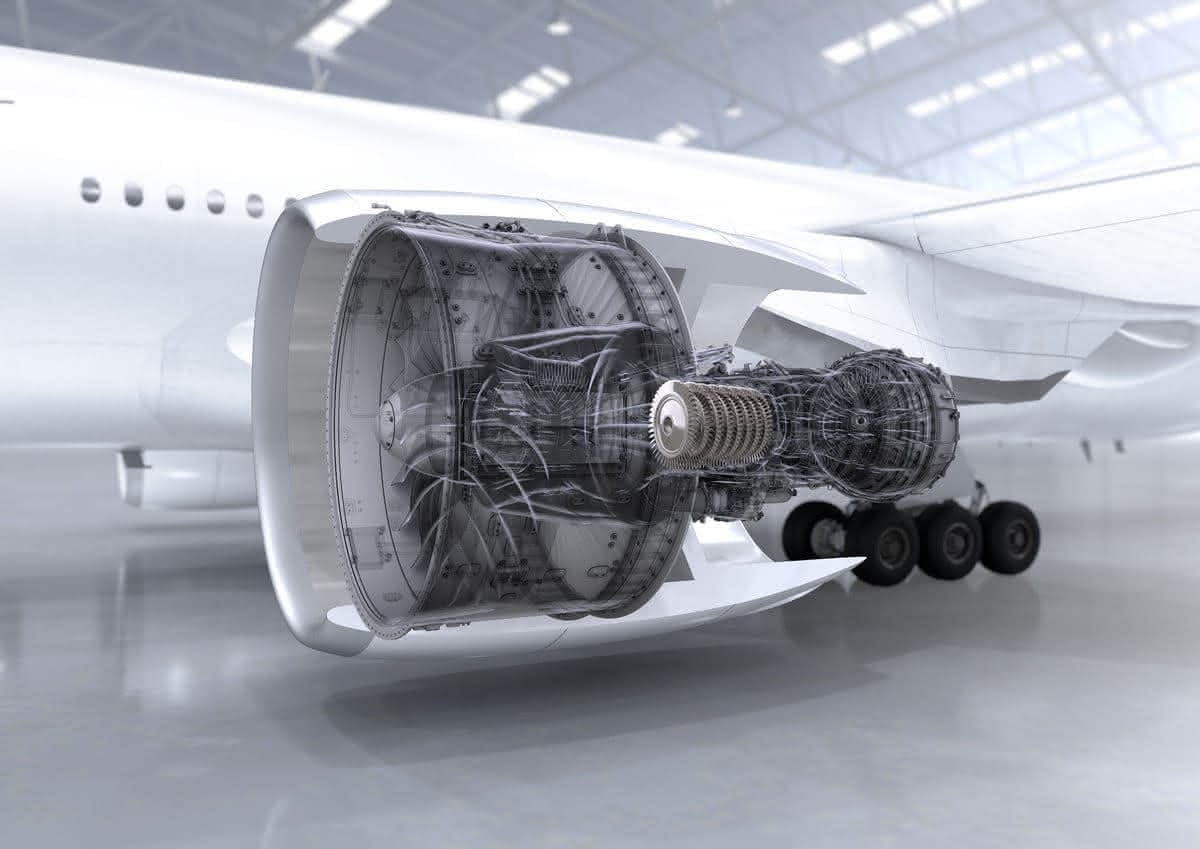

Revolutionise Your Production with Subtractive Manufacturing Excellence

Precision, Efficiency, and Reliability in Every Cut

Our state-of-the-art subtractive manufacturing services bring unparalleled precision and efficiency to your production line. Specialising in cutting, milling, and shaping a wide range of materials, we deliver parts that meet the most exacting standards.

Contact Us today to discuss our range of solutions & capabilities.

- Contact Us

3D Portal is an additive manufacturing company registered in England & Wales No: 14583437 with trading address of 9 Integra:MK Business Park, Thornton Chase, Linford Wood, Milton Keynes, MK14 6FD. VAT No: 448076670. The company is a subsidiary of Sadirah Industrials registered in England & Wales No: 15109209. Contact Us today to discuss our range of solutions & capabilities.

Our Location

9 Integra:MK Business Park | Thornton Chase | Linford Wood | Milton Keynes | MK14 6FD | UK

Email Us

info@3dportal.comSocial Media